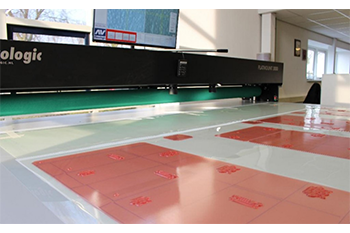

The Flatmount is AV Flexologic’s classic all-star flatbed mounting table for mounting flexo plates on mylar sheets. And by classic we don’t mean old-fashioned! On the contrary; in cooperation with our customers we have developed several great options and features over the past few years that have made this machine the most advanced, fastest and most reliable flatbed mounter available on the market, whilst still being very easy to operate.

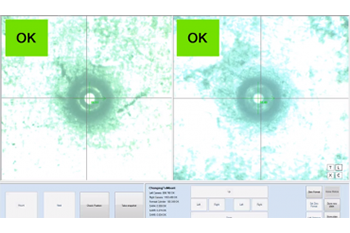

Once the first plate is in the right position, the overlay module enables the operator to take and store a snapshot of the mounting marks, which is then shown on the monitor. Whilst mounting the next plates, this snapshot is displayed in a faded way on the monitor as a reference point for the operator. The operator simply has to position the mounting marks of the next plate(s) over its (overlay) in exactly the same position

The system enables snapshots to be taken of these second and next plates as well, which can serve as a digital proof for quality control purposes before printing. Several hairline types are available. The picture on the monitor is adjusted automatically for outside light influences such as brightness, gamma, sharpness, shutter, white balance, and gain.

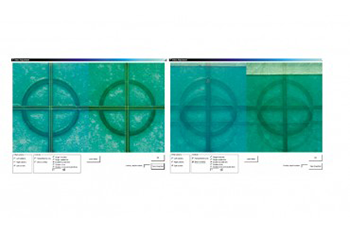

Image Recognition (patented)

Intelligent AV Flexologic software recognizes any mark, consequently the FAMM positions the plate with a precision down to 5 microns.

Overlay System (Patented)

Once the first plate is in the right position, the overlay module enables the operator to take snapshots of the mounting marks, which are then shown semi-transparently when mounting the other plates.

HD Ethernet Cameras

HD Ethernet Cameras

A high speed connection combined with sharp images, zoom up to 170x and a 40” monitor enables the operator to observe the machine mounting the plate with precision.

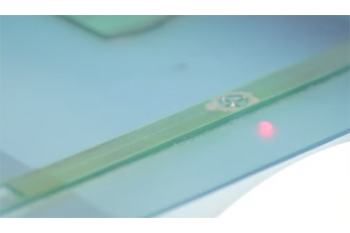

Laser pointers

Laser pointers

Designed to ensure quick positioning.

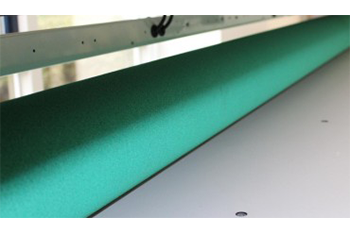

Pressure Roller (optional)

Pressure Roller (optional)

After positioning the printing plates, the pressure roller fixes the plate onto the Mylar. The pressure roller ensures air bubble free, quick and smooth mounting.

Camera encoders and a keypad

Camera encoders and a keypad

For easy operating the machine is equipped with camera encoders and a keypad. The encoders allow the operator to move the cameras by rotating them and with the keypad the operator inserts commands by simply pushing a button.

Customizable machine

Customized options, such as a specific clamping system or vacuum system can be added if needed.

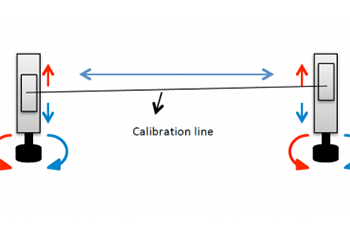

Digital Calibration of Camera Beam (patented)

The camera images are used in a calibration procedure to create a lookup table to digitally ‘straighten’ any deviations in the camera beam, down to 10 μm over the entire width of the camera beam / sleeve.

Mounting Table

The mounting table has various special applications to simplify the mounting even more. The machine is made of a sturdy steel frame with trespa top and is standard equipped with a so-called Matthews/Bobst locking system. Optionally you can request a clamping system and/or a vacuum system to fix the Mylar sheet on the table.

The camera rail is mounted on a high quality temperature treated and precise grinded beam. The cameras and the camera-beam construction are provided with highly accurate precision motors for computer controlled and automatic positioning.