The Fully Automatic Mounting Machine Prepress is suitable for printers who demand the highest standards. The machine uses patented image recognition and robotic positioning to achieve its incredible mounting speed, repeatability, consistency and accuracy. The FAMM won several awards, among others the FTA’s technical innovation award. It can handle high capacity and has an impressive return on investment.

Please note that the machine has not yet been produced and that the images and videos are shot using the FAMM for wide web as model. If you are interested in this machine, please contact AV Flexologic to request information about the development project.

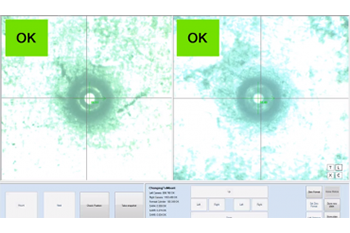

Image Recognition (patented)

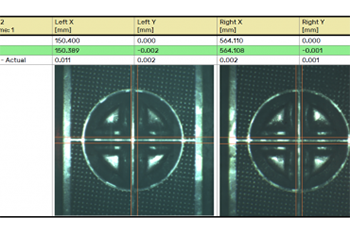

Intelligent AV Flexologic software recognizes any mark, consequently the FAMM positions the plate with a precision down to 5 microns.

Automatic positioning

A robotic manipulator automatically positions the flexo plates with a precision of 5 microns.

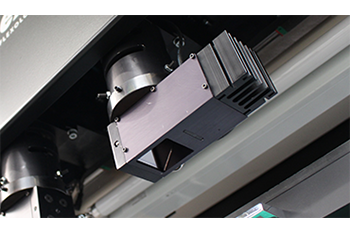

HD Ethernet Cameras

HD Ethernet Cameras

A high speed connection combined with sharp images and a zoom up to 170x enables the machine to mount the plates quickly and with high precision.

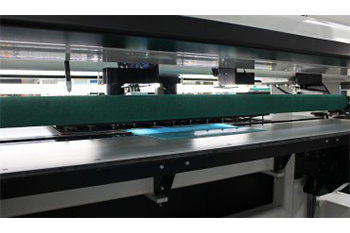

Conveyor belt

Conveyor belt

The operator simply places the to-be-mounted plates on the conveyor belt and the machine does the rest.

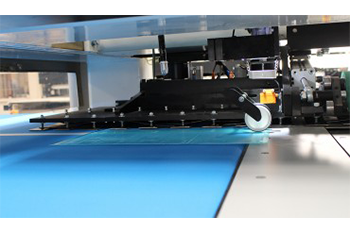

Pressure Roller

After positioning the printing plates, the pressure roller fixes the plate onto the sleeve or cylinder. The pressure roller ensures air bubble free, quick and smooth mounting.

Multiple safety features

To ensure risk-free operation, the FAMM is equipped with light beams and multiple other sensors that do not allow movement near to where the machine mounts the flexo plate.

Digital proof report of mounting results

At the end of a mount the machine goes back to the zero position and compares the actual position with the position where the mounting mark should be.

Workflow Fully Automatic Mounting Machine

The patented system is based on two co-ordinates (register-marks) applied on the photopolymer printing plate perpendicular to the print direction. Through automatic image recognition, interactive software and cameras the FAMM can read the digital positions of the flexo mounting marks.

Subsequently a robotic manipulator automatically positions the flexo plates with a precision of 5 microns. Next the FAMM mounts the plate onto the cylinder or sleeve with extreme accuracy. While the plates are automatically mounted onto the sleeves the operator is able to work on a different task in the production line.