The operator either manually enters the job information, or the information is sent to the machine using one of our workflow optimizing solutions. After selecting the job, the operator places the printing plate onto the table. Laser pointers aid with the initial positioning. After positioning the photopolymer plate, the operator elevates the vertically moving cylinder, lowers the pressure roller and rotates the cylinder using the foot pedal. After mounting the first sleeve / cylinder, the operator clicks on the keypad in front of the machine to go to the next sleeve / cylinder. Optionally using the overlay function for perfect color-to-color registration, the operator mounts the next plates onto the next sleeves / cylinders.

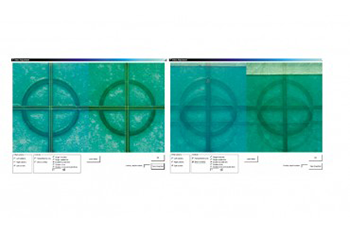

Overlay System (Patented)

Once the first plate is in the right position, the overlay module enables the operator to take snapshots of the mounting marks, which are then shown semi-transparently when mounting the other plates.

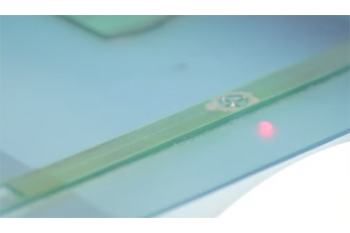

Laser pointers

Designed to ensure quick positioning.

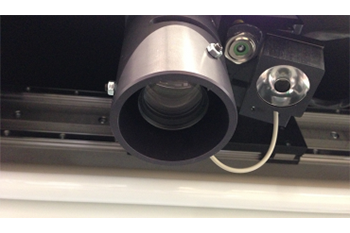

HD Ethernet Cameras

A high speed connection combined with sharp images, zoom up to 170x and a touchscreen enables the operator to mount the plate with highest precision.

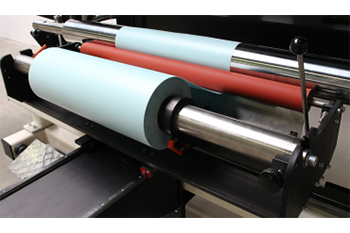

Vertical movement of cylinder (unique)

This feature enables a fixed focus of the cameras. It enhances precision and optimizes the workflow.

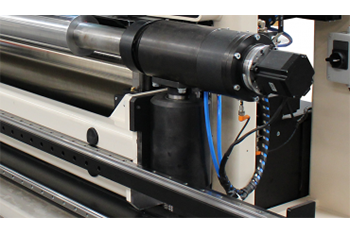

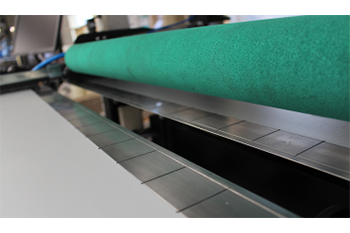

Pressure Roller

After positioning the printing plates, the pressure roller fixes the plate onto the sleeve or cylinder. The pressure roller ensures air bubble free, quick and smooth mounting.

Keypad on the machine

All essential commands to the machine can be given through this keypad, enabling an ergonomic workflow for the operator.

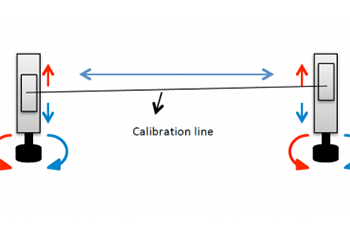

Digital Calibration of Camera Beam (patented)

The camera images are used in a calibration procedure to create a lookup table to digitally ‘straighten’ any deviations in the camera beam, down to 10 μm over the entire width of the camera beam / sleeve.

Cutting Knife, Tape applicator or Tape holder (optional)

Used to increase efficiency and ease-of-use.

Workflow Motorized Mounting Machine

The operator either manually enters the job information, or the information is sent to the machine using one of AV Flexologic’s workflow optimizing solutions. After selecting the job, the operator places the printing plate onto the table. Laser pointers aid with the initial positioning.

After positioning the photo-polymer plate, the vertically moving cylinder goes up, the operator lowers the pressure roller and rotates the cylinder using the foot pedal.

After mounting the first sleeve or cylinder, the operator clicks on the keypad in front of the machine to go to the next sleeve or cylinder. Optionally using the overlay function for perfect color-to-color registration, the operator mounts the next plates onto the next sleeves or cylinders.