Over the years this flexo printing plate mounter and proofer machine for the corrugated postprint industry has been highly valued by many customers from all over the world.

The system is based on two co-ordinates (register-marks) that are applied on the printing plate perpendicular to the print direction. The sturdy frame construction with heavy duty cylinder brackets and a temperature treated and grinded camera beam with double linear guiding ensures the best calibration and excellent results throughout the years. The motorized positioning of both cameras and cylinders simplifies the mounting job, which improves and accelerates results considerably.

This flexographic mounter is also equipped with a proofing drum for making proof prints after mounting, distortion calculation software and the mounter proofer is also supplied with a mirror that enables the user to mount using a plot or a design on the proof paper as reference,

- Compatible with ESKO PlatePatcher and Hybrid Patchplanner software.

- Compatible with most PDF type workflows. The machine can import the output file that contains the positions of the mounting marks. The cameras automatically move to the correct mounting positions.

- Connections with ERP settings for job entry.

- Barcode scanners to pull the job information with the coordinates from your database.

- Remote support through internet.

- Offline filling database that enables the input of new jobs from a separate computer.

Overlay System (Patented)

Once the first plate is in the right position, the overlay module enables the operator to take snapshots of the mounting marks, which are then shown semi-transparently when mounting the other plates.

Touchscreen monitor

For quick and easy job entry and job retrieval.

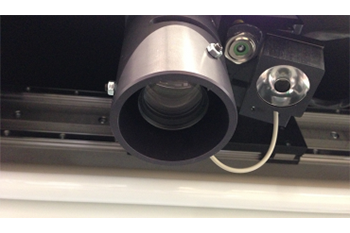

HD Ethernet Cameras

A high speed connection combined with sharp images, zoom up to 170x and a 40” monitor enables the operator to observe the machine mounting the plate with precision.

A fixed one-size-fits all mounting cylinder

A computer controlled electronic motor directly drives the cylinder (gearless). The mounting cylinder is standard provided with a locking strip for the so-called Matthews or Bobst system, however other systems can be realized as well.

Optional proofing cylinder

A proofing cylinder with digital adjustment for a perfect proof is available for the SAMM Postprint. In this case, after mounting the plate cylinder is automatically brought to the correct position for pulling a proof.

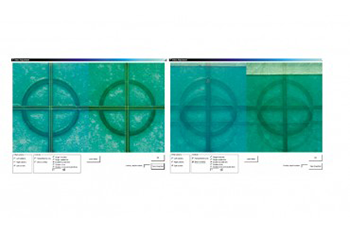

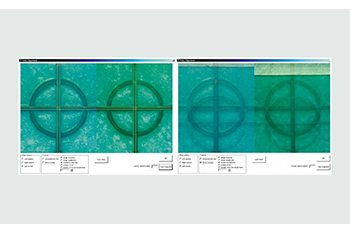

Overlay system explained

Once the first plate is in the right position, the overlay module enables the operator to take and store a snapshot of the mounting marks, which is then shown on the monitor. Whilst mounting the next plates, this snapshot is displayed in a faded way on the monitor as a reference point for the operator. The operator simply has to position the mounting marks of the next plate(s) over its (overlay) in exactly the same position.

The system enables snapshots to be taken of these second and next plates as well, which can serve as a digital proof for quality control purposes before printing. Several hairline types are available. The picture on the monitor is adjusted automatically for outside light influences such as brightness, gamma, sharpness, shutter, white balance, and gain.