The Semi-Automatic Mounting Machine (SAMM) Preprint belongs to the top range of AV Flexologic’s mounting equipment. The SAMM, available for cylinders and sleeves, combines conventional with automatic mounting, therefore you get best of both worlds. The automatic mounting system of the SAMM acts upon the crucial part of mounting, the positioning of the plate. The positioning is done by the machine instead of the operator, this results in high quality and consistent mounting. This patented machine is unique in the flexographic printing market.

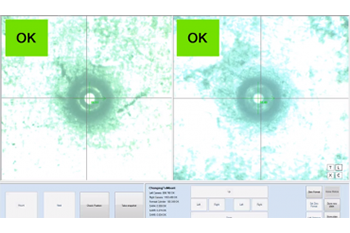

Image Recognition (patented)

Image Recognition (patented)

Intelligent AV Flexologic software recognizes any mark, consequently the SAMM positions the plate with a precision down to 5 microns. After mounting an automatic quality check is done, using image recognition, to ensure the precision of the mount.

Robotic positioning

Robotic positioning

Driven by the AV Flexologic software, the robotic table positions the mounting plate with high accuracy, each and every time. After positioning the vertically moving cylinder automatically comes up.

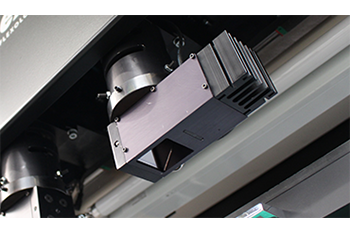

HD Ethernet Cameras

HD Ethernet Cameras

A high speed connection combined with sharp images and a zoom up to 170x enables the machine to mount the plates quickly and with high precision.

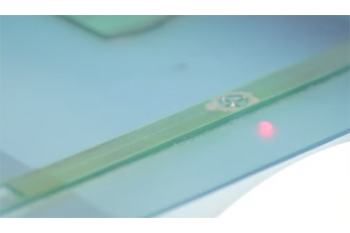

Vacuum table

Vacuum table

To ensure highly accurate positioning, the vacuum system fixates the plate to the robotic table before positioning.

Touchscreen monitor

For quick and easy job entry and job retrieval.

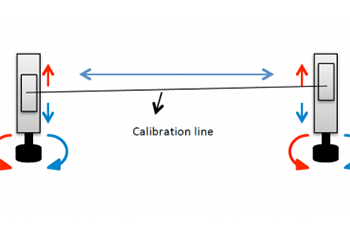

Digital Calibration of Camera Beam (patented)

The camera images are used in a calibration procedure to create a lookup table to digitally ‘straighten’ any deviations in the camera beam, down to 10 μm over the entire width of the camera beam / sleeve.

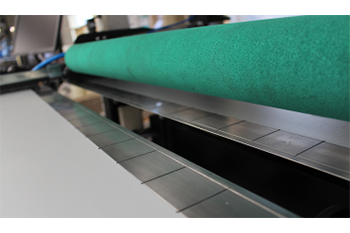

Pressure Roller

After positioning the printing plates, the pressure roller fixes the plate onto the sleeve or cylinder. The pressure roller ensures air bubble free, quick and smooth mounting.

Workflow Semi-Automatic Mounting Machine

The patented SAMM is equipped with an intelligent system that automatically monitors and controls the positioning of flexo plates. The system is based on two co-ordinates (register-marks) applied on the photopolymer printing plate perpendicular to the print direction. Due to the iteration between the cameras and the self-moving mounting table the plates will be positioned extremely accurate. After the positioning the vertically moving cylinder elevates automatically. Subsequently the operator lowers the pressure roller and rotates the cylinder using the foot pedal. The automatic positioning of the plates together with the mounting by the operator results in consistent high quality and constant repeatability.