The new technology of the SAMM 2.0 composes a masterpiece that is almost fully operator independent, high in accuracy and one of the fastest mounting machines in the world. With our image recognition technology systematically improved, the SAMM 2.0 features a staggering 30-second mounting speed almost fully operator independent.

- Eliminating waste and increasing environmental consciousness

- Eliminating press downtime due to mounting mistakes

- Higher productivity

- Faster job runs mean tighter runs: accuracy and speed are the main focus

- Automation means less operator dependency

- Efficiency means lower costs in the long run

- Quality reports allow tracing issues and quickly resolving them

- ERP integration for added efficiency and planning

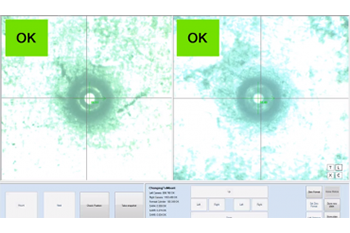

Reconocimiento de imágenes (patentado)

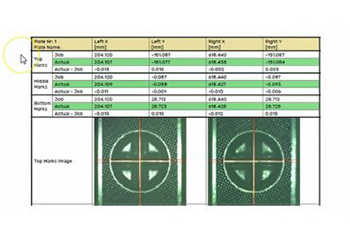

El software AV Flexologic inteligente reconoce cualquier marca, por lo que la SAMM posiciona la plancha con una precisión de hasta 5 micras. Después del montaje se realiza una comprobación de calidad automática, utilizando el reconocimiento de imagen, para garantizar la precisión del montaje

Synchronized Table (new)

Synchronized Table (new)

The synchronized table allows both sides of the mounting table to move together, granting lifting and lowering a perfect movement flow. This feature adds up to the SAMM 2.0 in durability of the table and stability of the mounting job.

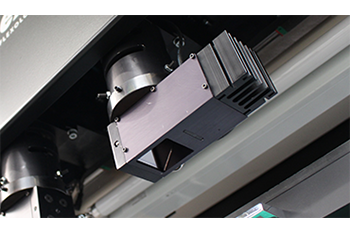

Cámaras HD Ethernet

Una conexión de alta velocidad combinada con imágenes nítidas y un zoom de hasta 170x permite a la máquina montar las planchas rápidamente y con alta precisión.

Motorised Front Table (new, optional)

Motorised Front Table (new, optional)

With this addition, the machine mounts one plate fully automatically, keeping the performance of the mounting job with an accuracy of 5 microns.

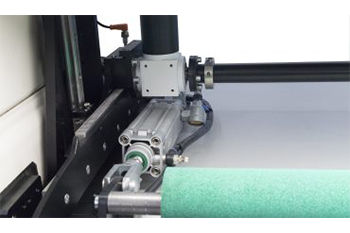

Automatic Pressure Roller (new)

The automatic pressure roller mounts every plate with the equal amount of pressure, ensuring a mounting job without air inclusions.

Quality Report (new)

After the mounting is completed, a Quality Report is generated in PDF in order to monitor the quality of the jobs.

Windows 10 (new)

Striving for the latest up to date technology, the SAMM 2.0 is equipped with Windows 10, which is fully compatible with our AVMOM software

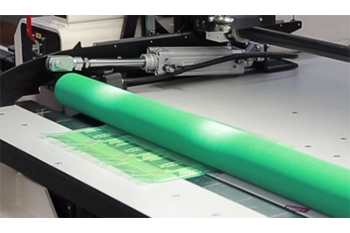

Nip Roll Tape Applicator (optional)

The Nip Roll assists the tape application and adds speed to the workflow by allowing a fast an accurate tape application and a minimum waste of materials.

Workflow Semi-Automatic Mounting Machine

The workflow of the new SAMM 2.0 is more versatile than the first generation. By adding the Motorised Front Table, the flexo plate mounter gets even closer to a fully automatic mounter. The operator has only to reload the plates as each one is mounted onto the plate with minimum input. The machine will then recognise the register marks that can either be crosshairs, dots or reversed negative dots and proceed to mount the flexo plates.

With the change in the printing industry, where lead times are shorter and job runs more frequent, the workflow for operating the SAMM 2.0 was streamlined. Thus, the SAMM 2.0 means more time for an operator to focus on other task, reduced press downtime due to mounting mistakes and higher productivity.