The semi-automatic flexo plate mouter (SAMM Postprint) for the corrugated flexo industry is AV Flexologic’s most advanced and automated mounting machine for mounting printing plates onto Mylars. The machine has been developed for our customers who demand the highest standards in mounting speed, repeatability, consistency and accuracy.

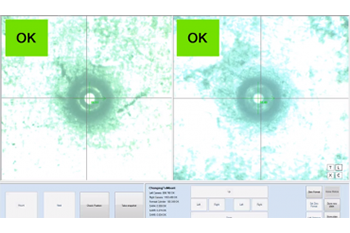

Image Recognition (patented)

Intelligent AV Flexologic software recognizes any mark, consequently the SAMM positions the plate with a precision down to 5 microns. After mounting an automatic quality check is done, using image recognition, to ensure the precision of the mount.

Automatic positioning

A robotic manipulator automatically positions the flexo plates with a precision of 5 microns.

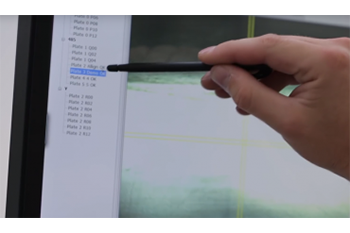

Touchscreen monitor

For quick and easy job entry and job retrieval.

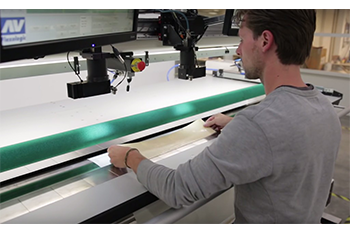

Vacuum table

To ensure highly accurate positioning, the vacuum system fixates the plate to the robotic table before positioning.

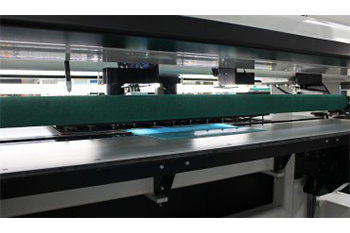

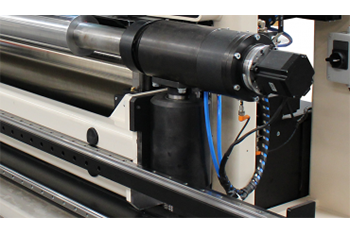

Pressure Roller

After positioning the printing plates, the pressure roller fixes the plate onto the sleeve or cylinder. The pressure roller ensures air bubble free, quick and smooth mounting.

A fixed one-size-fits all mounting cylinder

A computer controlled electronic motor directly drives the cylinder (gearless). The mounting cylinder is standard provided with a locking strip for the so-called Matthews or Bobst system, however other systems can be realized as well.

Vertical movement of cylinder (unique)

This feature enables a fixed focus of the cameras. It enhances precision and optimizes the workflow.

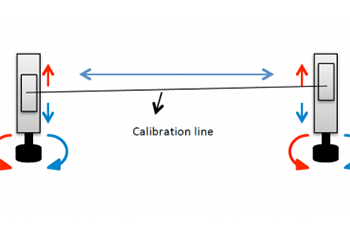

Digital Calibration of Camera Beam (patented)

The camera images are used in a calibration procedure to create a lookup table to digitally ‘straighten’ any deviations in the camera beam, down to 10 μm over the entire width of the camera beam / sleeve.

Workflow optimizing solutions

- Compatible with ESKO PlatePatcher and Hybrid Patchplanner software

- Compatible with most PDF type workflows. The machine can import the output file that contains the positions of the mounting marks. The cameras automatically move to the correct mounting positions.

- Connections with ERP settings for job entry

- Barcode scanners to pull the job information with the coordinates from your database

- Remote support through internet